How did we end up under the only black rain cloud in the entire sky? I don’t think it could have rained any harder if it tried. We were right on top of the Buffalo herd that we had been closing in on for the last hour and Armando our professional hunter said the magic words, “take the one at the front”. This would be the first shot at game for the 470 Mbogo project that I had been working on for the last year. Kutema spread the shooting sticks in front of me as I wiped the rain off my Leupold 1.5 to 5 power scope and placed the forend of my modified Ruger 77 mark II for the shot. A clear sight picture of the chest of the Buffalo, a slow trigger squeeze until the 470 went into recoil and then the resounding smack of the bullet hit. The bull reared up on impact, turned and disappeared. We waited for ten minutes and then followed up. Seventy five yards into the tracking we saw the buffalo lying on it’s side. With guns at the ready we approach slowly from behind at a forty five-degree angle but this bull was finished. The 500-grain Swift A-Frame had entered the front left chest area and penetrated to the right rear hindquarter. The first buffalo for the 470 Mbogo and a one shot kill, this was very satisfying indeed. Did the rain stop? I don’t think we really noticed.

How did we end up under the only black rain cloud in the entire sky? I don’t think it could have rained any harder if it tried. We were right on top of the Buffalo herd that we had been closing in on for the last hour and Armando our professional hunter said the magic words, “take the one at the front”. This would be the first shot at game for the 470 Mbogo project that I had been working on for the last year. Kutema spread the shooting sticks in front of me as I wiped the rain off my Leupold 1.5 to 5 power scope and placed the forend of my modified Ruger 77 mark II for the shot. A clear sight picture of the chest of the Buffalo, a slow trigger squeeze until the 470 went into recoil and then the resounding smack of the bullet hit. The bull reared up on impact, turned and disappeared. We waited for ten minutes and then followed up. Seventy five yards into the tracking we saw the buffalo lying on it’s side. With guns at the ready we approach slowly from behind at a forty five-degree angle but this bull was finished. The 500-grain Swift A-Frame had entered the front left chest area and penetrated to the right rear hindquarter. The first buffalo for the 470 Mbogo and a one shot kill, this was very satisfying indeed. Did the rain stop? I don’t think we really noticed.

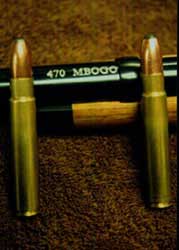

What is a 470 Mbogo? This is a cartridge that I designed to shoot a .475 bullet at an honest 2500 feet per second from a twenty four-inch barrel at a moderate pressure level. It is also a very easy cartridge to form brass for and a snap to reload. The brass is formed with one pass through the full length-sizing die using Mast Technologies 416 Rigby cylindrical brass. With the bullet seated to the overall length of 3.750 the brass holds 9 grains more water than the 460 Weatherby with a factory loaded round. My first rifle was built on a Ruger 77 Mk II that was originally chambered for the 416 Rigby. I had the barrel removed and took it to Cliff LaBounty to have it rebored to .475. For my reamer I contacted the people at JGS with the initial drawings of the cartridge that I wanted. We worked back and forth to get all the details finalised and with completed drawings I was able to forward these to RCBS to have them start on building a set of reloading dies.

What is a 470 Mbogo? This is a cartridge that I designed to shoot a .475 bullet at an honest 2500 feet per second from a twenty four-inch barrel at a moderate pressure level. It is also a very easy cartridge to form brass for and a snap to reload. The brass is formed with one pass through the full length-sizing die using Mast Technologies 416 Rigby cylindrical brass. With the bullet seated to the overall length of 3.750 the brass holds 9 grains more water than the 460 Weatherby with a factory loaded round. My first rifle was built on a Ruger 77 Mk II that was originally chambered for the 416 Rigby. I had the barrel removed and took it to Cliff LaBounty to have it rebored to .475. For my reamer I contacted the people at JGS with the initial drawings of the cartridge that I wanted. We worked back and forth to get all the details finalised and with completed drawings I was able to forward these to RCBS to have them start on building a set of reloading dies.

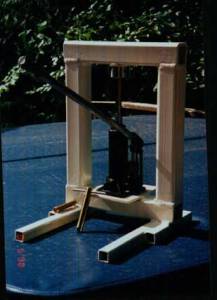

The brass required to make this cartridge is available through Mast Technologies of Las Vegas, Nevada. The brass comes without a headstamp in the cylindrical form. I didn’t want to go to Africa with improperly headstamped brass or brass without a headstamp so with a little help from Jay Bell of Mast Technologies I was able to headstamp my own brass. Jay was able to order a bunter for me with the lettering for the 470 Mbogo. A bunter is a cylindrical unit that they use to punch in the primer pocket and headstamp the brass during manufacturing. I ordered the one for the Mbogo with a small rifle primer pocket so that I wouldn’t damage any of the primer pockets that were already in the brass. I built my own press using a heavy steel frame and a four ton car jack. I had a hardened steel rod made that fit the inside shape of the brass perfectly. This was fitted to the top of the car jack in order to slip the brass over it and press the brass up into the bunter. The small rifle primer punch with a wrap of tape or some heat shrink on it makes a perfect guide to center the brass to be stamped to the bunter unit for the 470 Mbogo lettering. With the four-ton car jack the lettering comes out perfectly. The brass must be headstamped while it’s still in the cylindrical form.

The brass required to make this cartridge is available through Mast Technologies of Las Vegas, Nevada. The brass comes without a headstamp in the cylindrical form. I didn’t want to go to Africa with improperly headstamped brass or brass without a headstamp so with a little help from Jay Bell of Mast Technologies I was able to headstamp my own brass. Jay was able to order a bunter for me with the lettering for the 470 Mbogo. A bunter is a cylindrical unit that they use to punch in the primer pocket and headstamp the brass during manufacturing. I ordered the one for the Mbogo with a small rifle primer pocket so that I wouldn’t damage any of the primer pockets that were already in the brass. I built my own press using a heavy steel frame and a four ton car jack. I had a hardened steel rod made that fit the inside shape of the brass perfectly. This was fitted to the top of the car jack in order to slip the brass over it and press the brass up into the bunter. The small rifle primer punch with a wrap of tape or some heat shrink on it makes a perfect guide to center the brass to be stamped to the bunter unit for the 470 Mbogo lettering. With the four-ton car jack the lettering comes out perfectly. The brass must be headstamped while it’s still in the cylindrical form.

On to Page 2…